Curtis ML Duplex Air Compressor Dual 30 HP Pumps And Motors 240 Gal. Tank

This unit is ideal for a medium to large body shop. It will run sandblasting equipment and all air tools. This unit is ideal for any body shop.

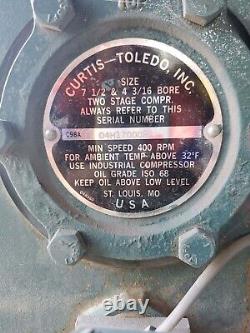

It actually gives you two air compressors one to run and one to use as a back up or heavy load situation. Pictures that are included are prior to the unit being wiped down! Literally wiped off unit looks almost new. This is a used unit Built in 2017 mounted on a 240 Gallon Tank, this unit is top-of-the-line. It is pressure lubricated has belt guard mounted air cooled after coolers. Low oil pressure shut down switches. Prewired control panel with dual selector or auto run. Patented Centro-Ring Pressure Lubrication System. Delivers 100% continuous duty over an extended service life since all critical components are properly lubricated. ML Series reciprocating compressors handle rugged, hot or dirty ambient conditions better than rotary compressors.Automatic tank drain simplifies maintenance. And the air cooled aftercooler increases air quality.

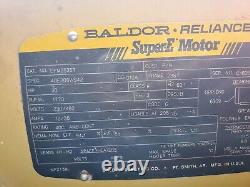

Also includes tank isolator pads that reduce vibration & noise. Two C98 2-Stage Pumps With 100% Cast-Iron Cylinders, Cylinder Heads, & Connecting Rods. Durable pumps deliver 204.4 CFM at 175 PSI; slow RPM extends pump life & reduces noise. Oversized tapered main roller bearings ensure long pump life. Low oil shut-off protects the pump. Premium finned intercooler maximizes heat dissipation. Metal intake filter housing is superior to plastic. Stainless-steel valve assemblies increase airflow & reliability.Two 30-HP NEMA-Designed Electric Motors With Automatic Stop/Start Control. Alternator control panel complete with magnetic starters can run as continuous or intermittant duty.

Robust, heavy-duty construction is built tough to last a lifetime in demanding working conditions. Automatic condensate tank drain valve simplifies maintenance. OSHA-Approved Totally Enclosed Metal Belt Guard. Heavy-duty stamped-steel belt guard protects both the drive belt and the operator. Unit is running perfectly when company closed.